Why Laser Marking is Superior to Hot Stamping for Security Seals

A security seal is only as effective as its identification number. You can have the strongest steel bolt in the world, but if the serial number rubs off due to friction or fades under the sun, that seal becomes anonymous—and an anonymous seal is a security liability.

For decades, hot stamping was the industry standard for numbering plastic seals. However, as supply chains become more digitized and automated, laser marking has emerged as the superior technology.

In this post, we compare these two printing methods and explain why custom laser printed seals are the investment you need to make for a secure chain of custody.

Quick Answer: Why Choose Laser Marking Over Hot Stamping?

Laser marking is superior because it burns the information directly into the material, creating a permanent, indelible mark that cannot be scratched off or removed by chemicals. Unlike hot stamping, which uses foil that can peel or fade, laser marking allows for tamper-proof numbering and high-resolution barcode security seals that remain scannable even after months of exposure to harsh weather.

1. The Traditional Way: What is Hot Stamping?

Hot stamping (or foil stamping) involves heating a metal die and pressing a layer of colored foil onto the surface of the plastic seal. It acts like a “tattoo” on top of the plastic.

-

The Pros: It creates a high-contrast look (e.g., white text on a red seal) that is easy to read with the naked eye from a distance.

-

The Cons: The foil sits on top of the plastic. Over time, friction from other cargo, exposure to UV rays, or contact with chemicals (like fuel) can cause the foil to flake or peel off. Once the number is gone, the seal is useless.

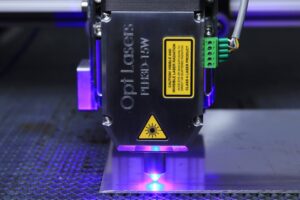

2. The Modern Standard: What is Laser Marking?

Laser marking does not add ink or foil to the surface. Instead, a high-intensity laser beam interacts with additives in the plastic, carbonizing the material to change its color permanently (usually turning it dark grey or black).

-

The Pros: The marking is part of the seal itself. It penetrates the surface. You cannot scratch it off without digging deep into the plastic body, which leaves obvious evidence of tampering.

3. Three Reasons Laser Marking Wins

A. Unmatched Durability in Harsh Weather

If your cargo travels on open flatbeds, railcars, or ocean vessels, it faces rain, saltwater, and scorching sun.

Hot stamped foil tends to become brittle and crack under UV exposure. Laser marking, however, is impervious to the elements. The “burned-in” text remains legible for the lifespan of the seal, ensuring that when the cargo arrives at its destination, the tamper-proof numbering is still readable.

B. Advanced Data: The Rise of Barcode Security Seals

Modern logistics relies on speed. Manually writing down a 10-digit serial number is slow and prone to human error.

-

Hot Stamping Limitations: Hot stamping dies are low-resolution. They cannot print clean, readable barcodes or QR codes.

-

Laser Capabilities: Lasers offer extreme precision. This allows for barcode security seals (Code 128, Code 39, QR Codes) that can be scanned instantly by handheld devices. This automation eliminates clerical errors and speeds up gate checks.

C. Impossible to Alter (Higher Security)

A common tampering technique involves “modifying” a serial number—for example, scratching off a “3” to make it look like a “1,” or using solvents to wipe away the print and re-stamp it.

-

Because laser marking changes the chemical structure of the plastic, it cannot be wiped away with solvents. Any attempt to mechanically alter the number will visibly damage the surface texture of the seal, raising an immediate red flag.

Comparison Table: Hot Stamp vs. Laser Mark

| Feature | Hot Stamping | Laser Marking |

| Method | Heated foil transfer | Carbonization of plastic |

| Durability | Low (Can peel/scratch) | High (Permanent) |

| Barcode Capable | No | Yes (QR & Linear Barcodes) |

| Tamper Resistance | Moderate (Can be altered) | High (Alteration destroys surface) |

| Cost | Lower | Slightly Higher |

| Best Use Case | Short-term storage | Long-haul & Automated Logistics |

Final Thoughts: Secure Your Data, Not Just Your Door

In the world of logistics, the data is the security. If you cannot read the number, you cannot verify the shipment.

While hot stamped seals are acceptable for short-term, low-risk applications (like fire extinguisher tags), custom laser printed seals are the mandatory choice for high-value cargo, cross-border shipments, and any operation utilizing barcode scanners.

Looking for permanent identification?

Acme Seals offers advanced laser marking on our full range of Bolt, Cable, and Plastic seals. Contact us today to customize your seals with your logo, barcodes, and unique numbering.